Lion Mould Extrusion have developed the world’s most technologically advanced line of extrusion dies, suitable for every segments of packaging and printing industry, such for the extrusion coating and laminating.

Lion Mould has designed Deckle System with is allowed to produce different width of the product without any leakage. Autoadjust system is also recommended to installed on the Die, which will be scan the thickness of the films or sheets, and report the results to the micro computer, with which can be used to improve the uniformly thickness and quality. With the need of suitable for various plastic materials, Lion Mould Developed different designs to solve this problem, Which are Coathanger design and T style Design.

With the Extrusion Dies made by Lion Mould, you can easily made films, sheets, hollow boards with any plastic material you want.

| TYPE |

extruder die for lamination extrusion line |

| die width range |

500~5000mm |

| die lip gap ragne |

0.7-1mm |

| suitable material |

PP/PE/EVA/EEA |

| capacity |

100-500kg/hr |

| deckle system |

internal and external deckle are available |

| application |

lamination on non-woven, paper and plastic film extrusion machine single layer, multi layers |

| TYPE |

extrusion die for Hollow profile extrusion line |

| die width range |

300~3000mm |

| die lip gap ragne |

2-12mm(PP) / 4-20mm(PC) |

| suitable material |

PP/PC |

| capacity |

100-700kg/hr |

| deckle system |

internal and external deckle are available |

| application |

building board / billboard extrusion line single layer, multi layers |

| TYPE |

extruder die for film extrusion line |

| die width range |

500~4000mm |

| die lip gap ragne |

0.5~1.2mm |

| suitable material |

CPP/PE/PET |

| capacity |

100-600kg/hr |

| deckle system |

internal and external deckle are available |

| application |

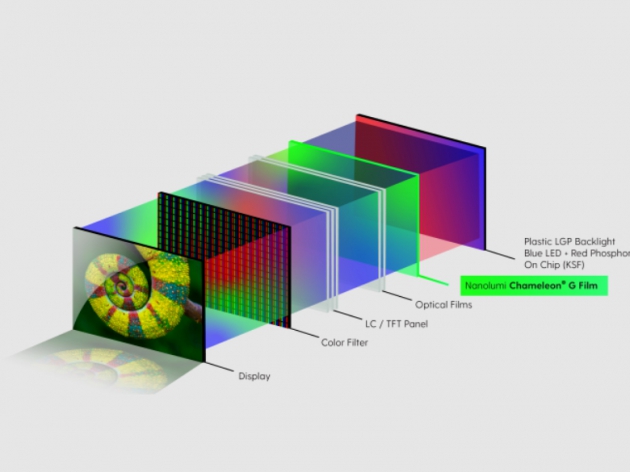

Breathable/ Bubble Wrap/foodstuff packing film/optical film/stationary film / packing film extrusion line/single layer, multi layers |

{php $tags=tag

("moduleid=5&condition=username='$username' and

status=3&pagesize=5&template=null");}